THE DOGRUN

a place to share ideas

How Will Confluence Park Be Constructed?

Posted by sunniediaz on 3/1/17 at 4:53 pm

Lake|Flato’s collaboration with the San Antonio River Foundation (SARF), Rialto Studio, Andrew Kudless of Matsys, Architectural Engineers Collaborative (AEC), CNG Engineers, and Spawglass Contractors has magically evolved the vision of Confluence Park into a pavilion that responds to and enhances the surrounding natural environment. While capturing and treating its own water, the petals of the pavilion at Confluence Park are meant to inspire its occupants and offer an interactive learning experience about the San Antonio River and its watershed.

Since the early phases of our design process, constructability has always been a topic of conversation key to transitioning this park’s idea into a reality. Kreysler & Associates were brought on board to help our design team bring our idea to reality. Team members from Lake|Flato (L|F), Matsys and the SARF recently visited Kreysler's fabrication studio to check on the progress, and now we can report back to you on your question of how will Confluence be constructed?

Located just north of Oakland, California's busy city and on the border of Napa’s beautiful vineyards, sits a 35,000 sq. ft. fabrication studio that’s testing the boundaries of the world’s most cutting edge CNC (Computer Numerical Control) routers and robotics technology. Kreysler & Associates are experts to say the least, in working with FRP (Fiber Reinforced Polymer) to design and construct the most innovative fabrications for architectural, sculptural and industrial applications, and has been doing so since 1982.

So — how are these concrete petals going to be made? We know to cast anything out of concrete, there has to be a formwork to create the desired shape in construction. These petals are the same, except the process to make this formwork is slightly more complicated than a typical tilt-wall panel.

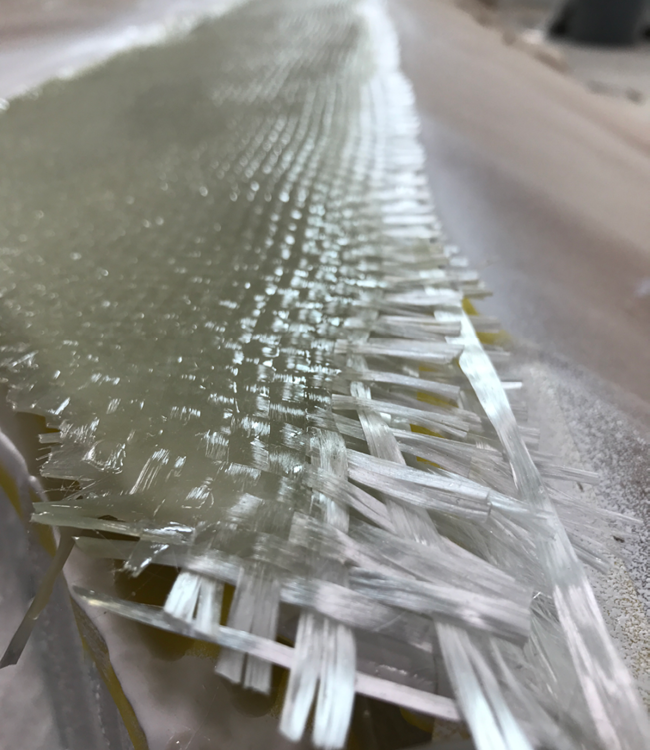

In short, the petals of Confluence Park are being carved out of EPS (Expanded Polystyrene Foam), then being cast over with layers of fiberglass mesh, resin and balsa wood “calendared sheets” to create the formwork. Each petal is made of three pieces of formwork: two underside panels, and one backform panel. They are fastened together by built in aluminum 'keys' with two continuous side panels. Here’s how the process looks in Kreysler’s Shop:

Kreysler receives these 3' x 4' x 24' blocks of EPS:

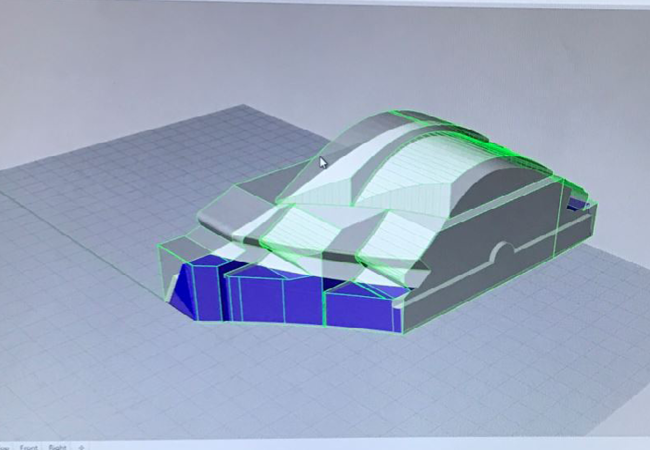

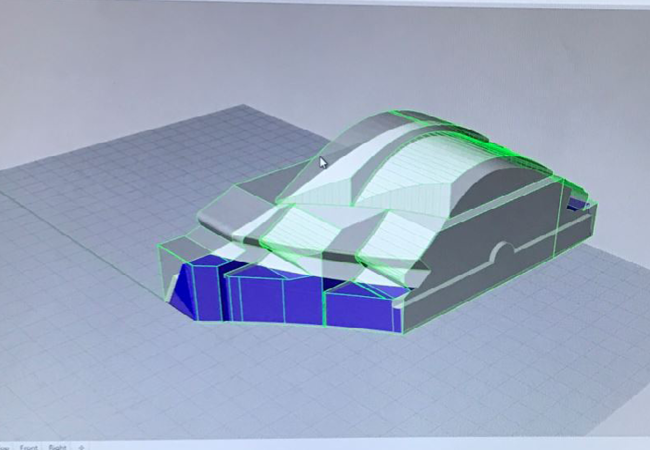

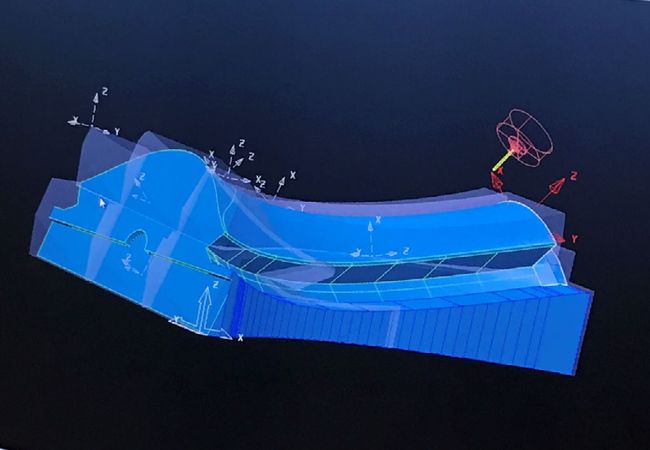

When Kreysler receives our Rhino model of the petals, these two computer-savvy fabricators slice and dice the model into software programs to begin cutting away at the foam.

When Kreysler receives our Rhino model of the petals, these two computer-savvy fabricators slice and dice the model into software programs to begin cutting away at the foam.

The first tool is programmed to "cut the fat" off the large chunks of EPS. Kreysler models the desired rough cuts in the software, and run the foam through the hot-wire machine to prepare it for the larger CNC.

The first tool is programmed to "cut the fat" off the large chunks of EPS. Kreysler models the desired rough cuts in the software, and run the foam through the hot-wire machine to prepare it for the larger CNC.

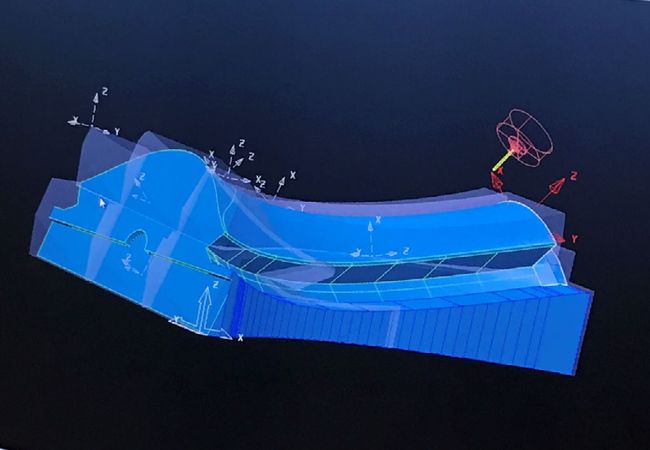

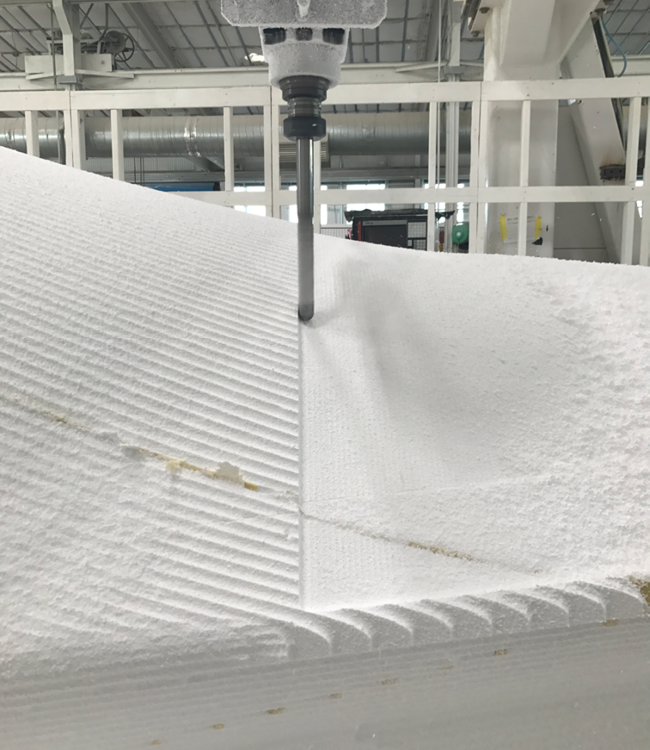

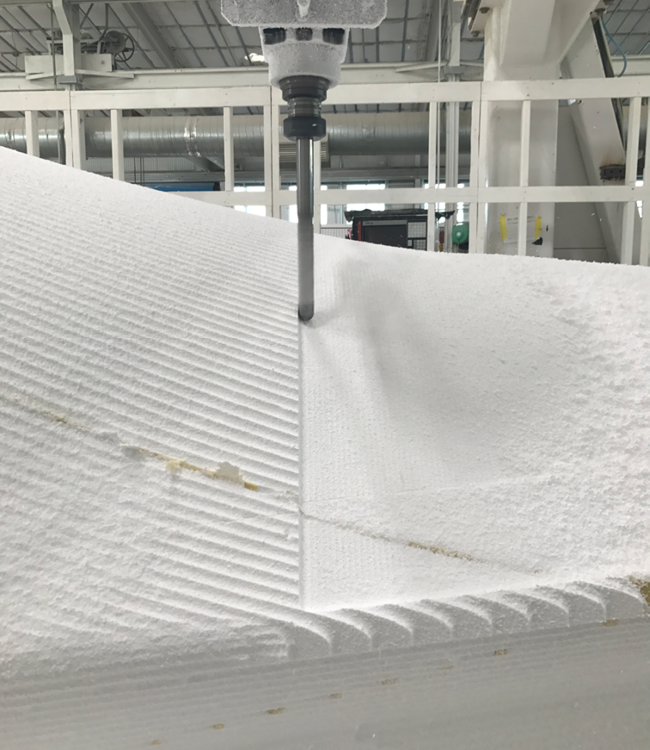

These hot-wired pieces of foam are then analyzed through PowerMILL Pro, which preps them to be routed by the large 5-axis CNC Router. The 5-axis router takes many passes on the block of foam — starting out with larger rough cuts, down to the finishing toolpaths of the 27' tall petals.

These hot-wired pieces of foam are then analyzed through PowerMILL Pro, which preps them to be routed by the large 5-axis CNC Router. The 5-axis router takes many passes on the block of foam — starting out with larger rough cuts, down to the finishing toolpaths of the 27' tall petals.

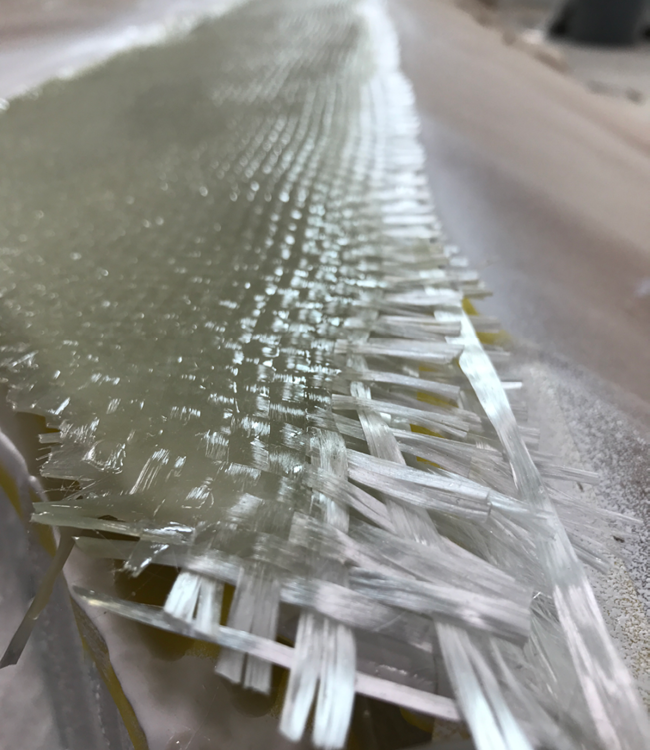

The blocks of EPS are then covered in sheets of good ole aluminum foil! This prevents the resin from eating away at the foam causing failures in the formwork. Layers of fiberglass reinforced resin are applied to the shape, followed by 1 1/2" thick calendared end-grain sheets of balsa wood which are able to form the curved shapes that typical wood boards wouldn’t be able to form.

The balsa gives strength and structure to the formwork, and another layer of fiber reinforced resin is applied over the balsa wood. This forms a 'sandwich panel' which, because of the wood core, is much stiffer than a single layer and much lighter than a 2" thick buildup of fiberglass

The blocks of EPS are then covered in sheets of good ole aluminum foil! This prevents the resin from eating away at the foam causing failures in the formwork. Layers of fiberglass reinforced resin are applied to the shape, followed by 1 1/2" thick calendared end-grain sheets of balsa wood which are able to form the curved shapes that typical wood boards wouldn’t be able to form.

The balsa gives strength and structure to the formwork, and another layer of fiber reinforced resin is applied over the balsa wood. This forms a 'sandwich panel' which, because of the wood core, is much stiffer than a single layer and much lighter than a 2" thick buildup of fiberglass

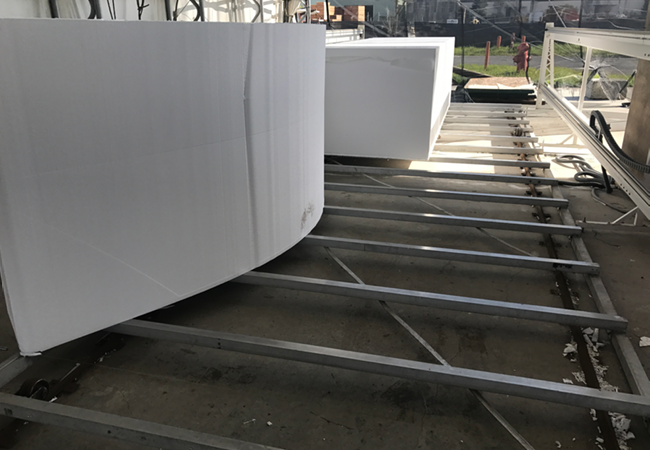

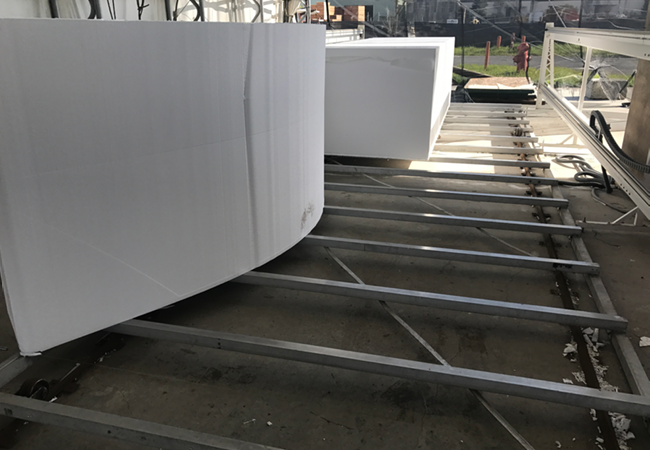

Each of the form panels, are removed from the EPS when ready, and sanded down to perfection in the shop. Steel trusses are tabbed into the formwork for strength when the mold heads out the door for transportation.

Each of the form panels, are removed from the EPS when ready, and sanded down to perfection in the shop. Steel trusses are tabbed into the formwork for strength when the mold heads out the door for transportation.

The panels are assembled with aluminum keys that are molded directly into the fiberglass and align with one another to be anchored together with thru-bolts. They're assembled in the shop, and once the finishing touches are applied, they're taken apart and loaded up on flat bed trucks to head out to the job site in San Antonio!

The panels are assembled with aluminum keys that are molded directly into the fiberglass and align with one another to be anchored together with thru-bolts. They're assembled in the shop, and once the finishing touches are applied, they're taken apart and loaded up on flat bed trucks to head out to the job site in San Antonio!

The first "C" petal formwork was shipped and arrived on site Monday February 27!

The first "C" petal formwork was shipped and arrived on site Monday February 27!

When Kreysler receives our Rhino model of the petals, these two computer-savvy fabricators slice and dice the model into software programs to begin cutting away at the foam.

When Kreysler receives our Rhino model of the petals, these two computer-savvy fabricators slice and dice the model into software programs to begin cutting away at the foam.

The first tool is programmed to "cut the fat" off the large chunks of EPS. Kreysler models the desired rough cuts in the software, and run the foam through the hot-wire machine to prepare it for the larger CNC.

The first tool is programmed to "cut the fat" off the large chunks of EPS. Kreysler models the desired rough cuts in the software, and run the foam through the hot-wire machine to prepare it for the larger CNC.

These hot-wired pieces of foam are then analyzed through PowerMILL Pro, which preps them to be routed by the large 5-axis CNC Router. The 5-axis router takes many passes on the block of foam — starting out with larger rough cuts, down to the finishing toolpaths of the 27' tall petals.

These hot-wired pieces of foam are then analyzed through PowerMILL Pro, which preps them to be routed by the large 5-axis CNC Router. The 5-axis router takes many passes on the block of foam — starting out with larger rough cuts, down to the finishing toolpaths of the 27' tall petals.

The blocks of EPS are then covered in sheets of good ole aluminum foil! This prevents the resin from eating away at the foam causing failures in the formwork. Layers of fiberglass reinforced resin are applied to the shape, followed by 1 1/2" thick calendared end-grain sheets of balsa wood which are able to form the curved shapes that typical wood boards wouldn’t be able to form.

The balsa gives strength and structure to the formwork, and another layer of fiber reinforced resin is applied over the balsa wood. This forms a 'sandwich panel' which, because of the wood core, is much stiffer than a single layer and much lighter than a 2" thick buildup of fiberglass

The blocks of EPS are then covered in sheets of good ole aluminum foil! This prevents the resin from eating away at the foam causing failures in the formwork. Layers of fiberglass reinforced resin are applied to the shape, followed by 1 1/2" thick calendared end-grain sheets of balsa wood which are able to form the curved shapes that typical wood boards wouldn’t be able to form.

The balsa gives strength and structure to the formwork, and another layer of fiber reinforced resin is applied over the balsa wood. This forms a 'sandwich panel' which, because of the wood core, is much stiffer than a single layer and much lighter than a 2" thick buildup of fiberglass

Each of the form panels, are removed from the EPS when ready, and sanded down to perfection in the shop. Steel trusses are tabbed into the formwork for strength when the mold heads out the door for transportation.

Each of the form panels, are removed from the EPS when ready, and sanded down to perfection in the shop. Steel trusses are tabbed into the formwork for strength when the mold heads out the door for transportation.

The panels are assembled with aluminum keys that are molded directly into the fiberglass and align with one another to be anchored together with thru-bolts. They're assembled in the shop, and once the finishing touches are applied, they're taken apart and loaded up on flat bed trucks to head out to the job site in San Antonio!

The panels are assembled with aluminum keys that are molded directly into the fiberglass and align with one another to be anchored together with thru-bolts. They're assembled in the shop, and once the finishing touches are applied, they're taken apart and loaded up on flat bed trucks to head out to the job site in San Antonio!

The first "C" petal formwork was shipped and arrived on site Monday February 27!

The first "C" petal formwork was shipped and arrived on site Monday February 27!